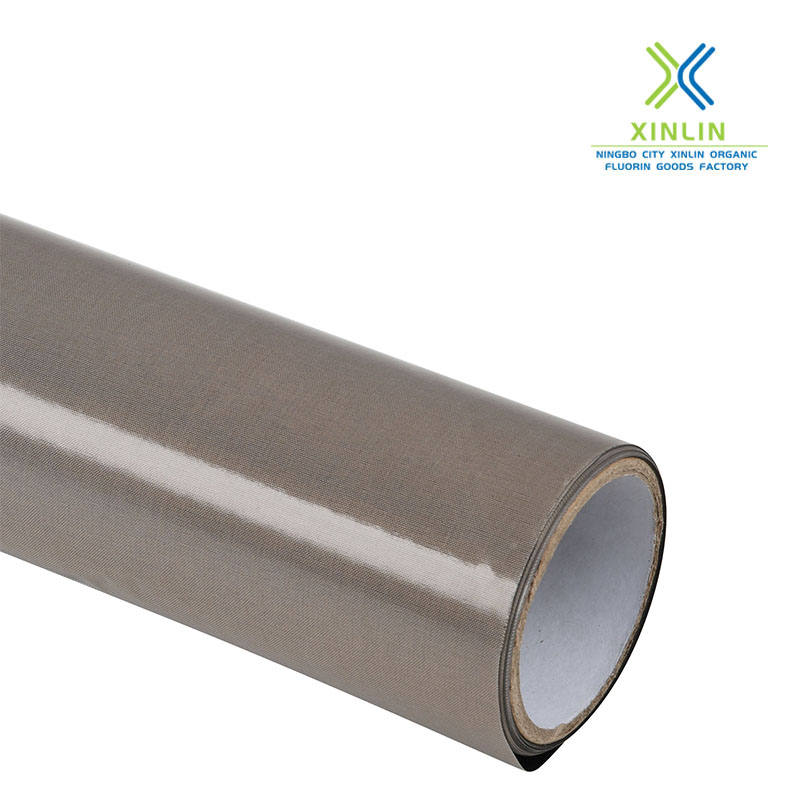

PTFE high temperature cloth is also a product of the co […]

PTFE high temperature cloth is also a product of the continuous development of chemical synthesis technology in the 1960s and 1970s. PTFE high-temperature cloth is mainly synthesized by fiber. This fiber is aramid fiber. This fiber is characterized by being relatively thick (dyeing on PTFE high-temperature cloth) and long and relatively tight. People use this material to make kite strings.

In the dyeing process of PTFE high temperature cloth, the di step is to brew, that is, to make PTFE high temperature cloth in an aqueous dye solution. After a period of time, we will find that the dye content in the aqueous solution is greatly reduced. The brewing has reached an equilibrium state. The amount of dye reduced in water is the amount of dye transferred to PTFE high-temperature cloth.

After the PTFE high-temperature cloth is made by foaming, we still have to deal with it, because if you squeeze it into your hand, you will find that the dye can be squeezed out again. At this time, coloring is needed, and the coloring process is divided into drying and spraying processes. Drying is to put the PTFE high temperature cloth under the sun to dry, of course, it can also be dried by the machine. After the PTFE high temperature cloth is dried, spraying the polytetrafluoroethylene solution can ensure that the PTFE high temperature cloth does not fade.

Copyright © Ningbo Xinlin Polymer Material Co. LTD. All Right Reserved Technical Support : HWAQ